SeeNous Condition Monitoring and Fault Diagnosis Platform

Prevent unplanned production downtime by detecting rotating equipment failures early.

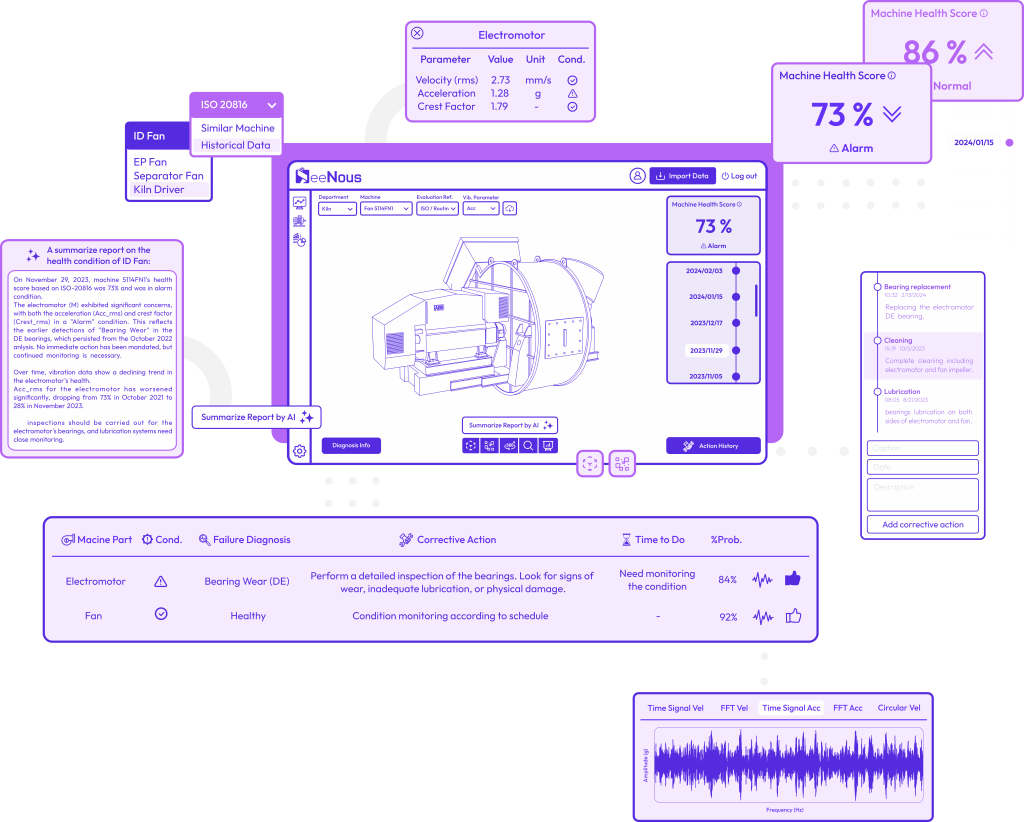

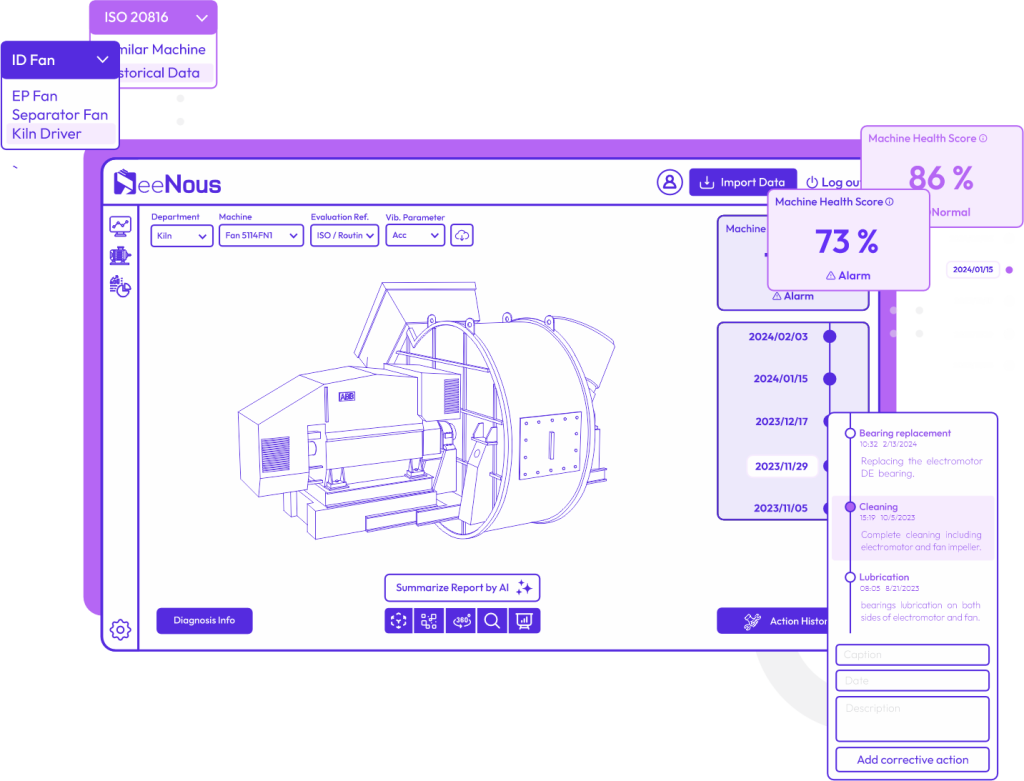

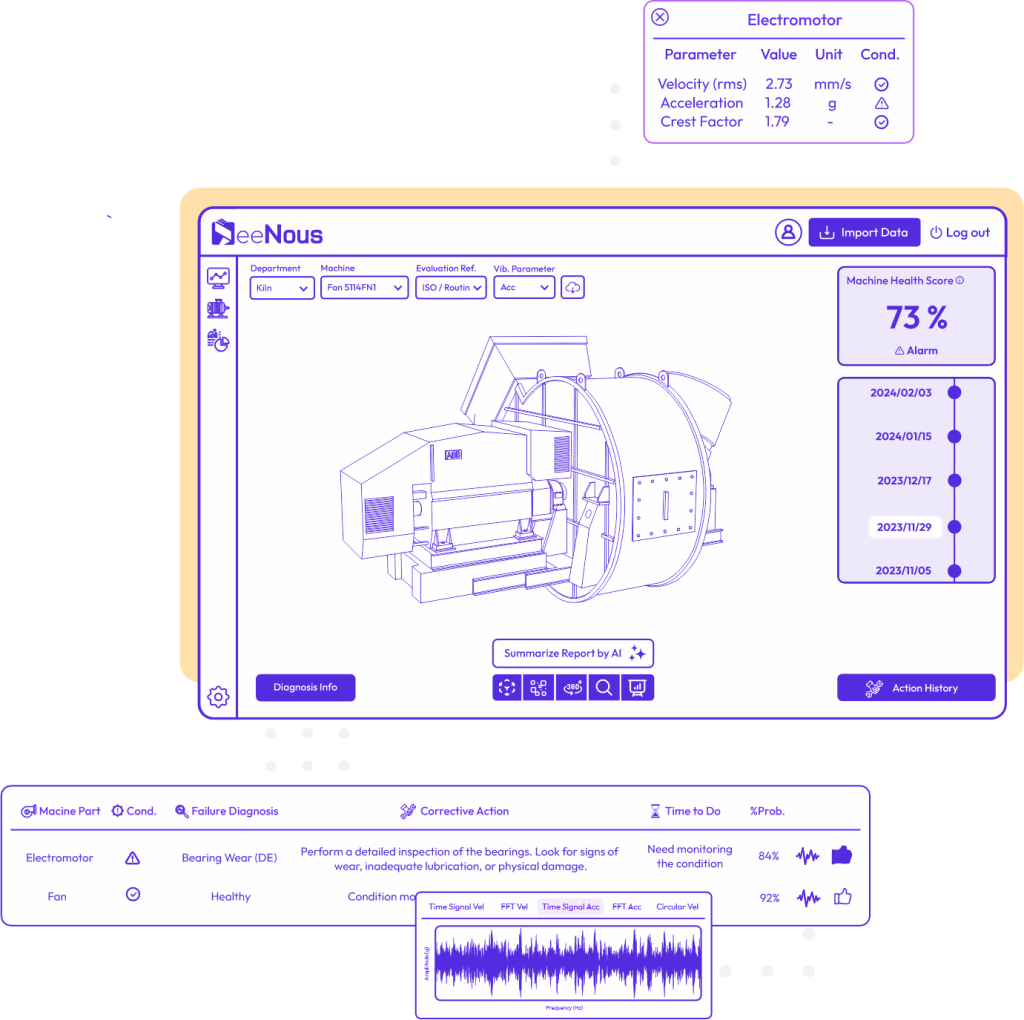

Digital Twin Based Dashboard

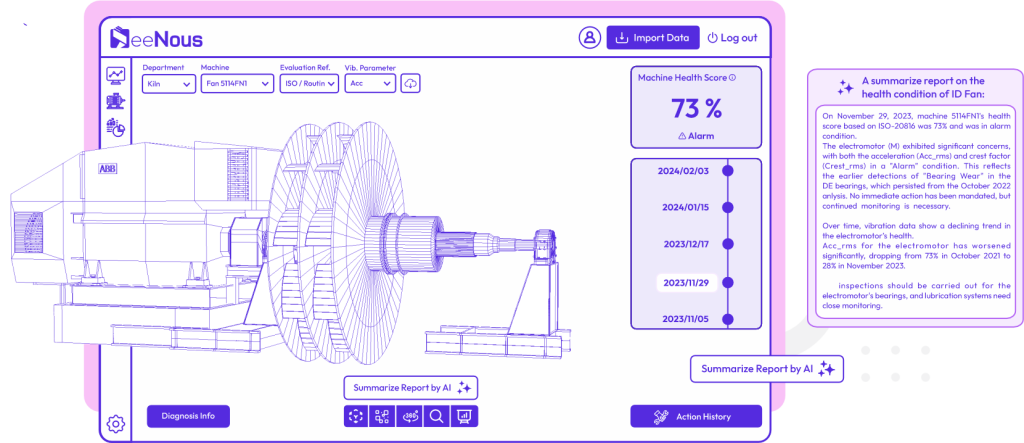

In the SeeNous dashboard, you can visually monitor and report the health status of your equipment across three levels — the entire production line, departments, and individual machines. With SeeNous Generative AI, you can also generate real-time textual reports.

Vibration Data Collection with Sensors

SeeNous uses wireless IoT-based sensors to collect vibration data from rotating equipment. Its wireless data collectors can operate in both route and off-route modes. You can also use your factory’s existing portable data collectors, which are fully compatible with the SeeNous software platform.

AI-Powered Fault Detection

The SeeNous AI is trained on real-world vibration data collected from industrial equipment. It detects common rotating machinery faults such as unbalance, misalignment, looseness, bearing defects, gearbox issues, and more.

• Detect common faults such as misalignment, looseness, bearing failures, and more.

• Compare your equipment’s health with similar machines in the SeeNous database.

• Interpret diagnostic results, explain the causes, and suggest corrective actions to resolve issues.

• Using SeeNous wireless data collectors

• Compatible with your factory’s portable data collectors and previous data history

• Can be used as a handheld vibrometer for ad-hoc condition monitoring outside routine schedules

• Visualize equipment health and heatmaps based on vibration parameters

• Record corrective actions taken by engineers and integrate with CMMS software

• Generate textual reports of equipment and maintenance actions using generative AI

Testimonials

See what people have to say about us

Reduce Unplanned Downtime and Boost Factory Profitability

Over 85% of rotating equipment failures can be predicted through vibration analysis.

Cloud Access to Data and Reports

Cloud access to data and reports on the SeeNous platform allows users to access all machine condition information anytime, anywhere, without installing software or being on-site. Vibration and performance data are securely stored and analyzed in the cloud. Through the web-based dashboard, users can track trends, view smart alerts, and generate analytical reports, enabling faster and more accurate maintenance decisions. This feature also enhances collaboration between technical and management teams, boosting overall organizational productivity.

Text-Based Equipment Health Reporting

The text-based reporting feature on the SeeNous platform automatically analyzes the health of rotating equipment and presents it in textual reports. These reports include a summary of the machine’s current condition, vibration anomalies, alert levels, and preventive maintenance recommendations. Using AI and historical data, the system generates reports in a style similar to expert technical analysis, allowing users to make informed decisions without interpreting charts. This feature accelerates decision-making, reduces dependence on human analysts, and improves the accuracy of condition monitoring.

Corrective Action Issuance and CMMS Integration

The SeeNous platform enables automatic issuance of corrective actions and direct integration with CMMS systems. Upon detecting a fault or critical alert, the system intelligently records recommended corrective actions and sends them to the maintenance module or your organization’s CMMS software. This process ensures work orders are automatically created, prioritized, and assigned to the technical team. With this integration, the detection-to-action cycle runs seamlessly, preventing rework and delays in maintenance.

SeeNous Investors and Business Partners